rockwell hardness test scale b|rockwell b hardness scale chart : retailer Have you ever wondered what those mysterious numbers on a metal part mean? In this blog post, we’ll dive into the fascinating world of hardness testing and explore the different scales used to measure a . Porcentagem de jogo para juniores. A simplicidade deste jogo sobre o cálculo da porcentagem de um número inteiro online o torna adequado para todos os públicos, especialmente para crianças de escolas e faculdades. Depois de alguns jogos, as crianças vão dominar este conceito e este tipo de cálculo. Lembrete do curso : números .

{plog:ftitle_list}

WEBLe 888 est "LE" couteau à viande par excellence de la marque. Tranchant acéré, bonne prise en main, facilité d'affûtage avec un simple fusil ovoïde, il ravira vos convives et habillera élégamment votre table. . Perceval a .

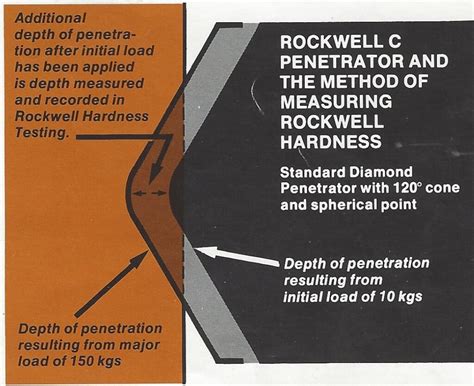

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .

Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables .Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 .

Have you ever wondered what those mysterious numbers on a metal part mean? In this blog post, we’ll dive into the fascinating world of hardness testing and explore the different scales used to measure a .Most designers try to convert their hardness testing scales to more suitable ones like Rockwell hardness B and C scales. This article compares two types of Rockwell hardness to help you .

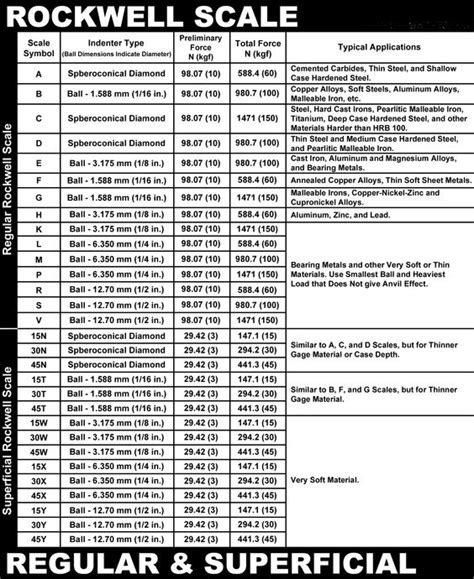

Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in the “Regular” Rockwell scale). Total test forces range from 15kgf to 150 kgf (superficial and regular) to 500 to 3000 kgf .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers .The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 .

The scope of use of every test is different but the most common method is Rockwell. The Rockwell hardness B scale is used for soft or mild metal materials. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are . Know more about scales of Rockwell Hardness test or other popular hardness testing methods by visiting our .

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

Superficial Scales. The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell hardness tester: 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y Polymer/Plastic .

The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. The scale follows an even subdivision of 0.002 mm (2 µm), so that reaching half the reference depth also corresponds to half the maximum hardness value (Rockwell hardness value 50). When diamond cones are used, the Rockwell scale is .Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: HRE 1/8” diameter tungsten carbide ball indenter, 100 kgf major load

Rockwell scales allow you to follow the standard scale tables and rules to get the accurate values of the hardness of your test material. + 86 755 61301520 [email protected] To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range; Hardness Conversion Chart - Rockwell "C" Hardness Range; Hardness vs Minimum Thickness Chart; Rockwell Scale-Indenter-Load Chart; Contact Us. About Us; Store Policies; Blog In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.

q bottle

There are several alternative scales, the most commonly used being the "B", and "C" scales. Both express hardness as an arbitrary dimensionless number. The B-scale is used for softer materials (such as aluminum, brass, and softer steels). It employs a hardened steel ball as the indenter and a 100kg weight to obtain a value expressed as "HRB".In conversion scales, common terms which should be first understood are scales, symbol, indenter and load or test force. All of these tables are based on these terms. For any hardness test, these tables are used for conversion of values from one test to another to get accurate results. . Rockwell B Hardness Range Hardness Conversion Chart for .The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.the Rockwell hardness test ( scales and hardness range according to Table 1) for metallic materials. NOTE — For certain materials, the hardness range may be narrower than those indicated. 2 REFERENCE The following Indian Standard contains provisions which through reference in this text, constitutes

The various indenter types combined with a range of test loads form a matrix of Rockwell hardness scales that are applicable to a wide variety of materials. Rockwell B and Rockwell C are the typical tests in this facility. The Rockwell B penetrator is a 1.59mm (1/16 inch) diameter tungsten-carbide ball and the major load isThe Diamond Hardness Test is another name for any scale that employs a diamond indenter. Amount of the total test load; B; scale division; and C. The regular and superficial varieties each require the application of nine separate Rockwell scales.Rockwell to Brinell conversion chart (Brinell, Rockwell A,B,C) Struers hardness conversion table (Vickers, Brinell, Rockwell B,C,D) This page was last edited on 18 December 2023, at 21:15 (UTC). Text is available under the Creative Commons Attribution-ShareAlike 4.0 License .

Find the hardness conversion for Rockwell B scale or high hardness range here. Download as PDF or get the Rockwell conversions right away.Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.Brinell [HB] is one of the most common units used for listing the hardness of steel materials. The test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC/HRB], is that the whole range is .

The Rockwell B-scale can be used in the case of softer materials such as brass, aluminum, and softer steel. It utilizes a hardened steel ball as an indenter along with a 100kg weight in order to derive a value, which is expressed as ‘HRB’. . The indenter, as well as the test-piece of the Rockwell hardness tester, should be cleaned well in .Rockwell Hardness Test (HRC) C scale (HRA) A. 60kgf diamond conical indenter (HRB) B. 100kgf diameter. 1.6mm (1/16ln) ball . Rockwell Hardness test is the most widely used method but in some cases Vickers Hardness testing method has to be used especially when thin parts have to be tested. It is important to look up the hardness scale .The Rockwell hardness test involves indenting the surface of a material with a diamond cone or steel ball indenter and measuring the depth of the resulting indentation. . Rockwell B scale (RHB): This scale is used for testing harder materials, such as brass, mild steel, and annealed copper alloys. The load applied is 100 kgf and the diamond .Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).

EXAMPLE 70 HR30N = Rockwell superficial hardness of 70 measured on the 30 N scale with a total test force of 294,2 N. 4.4 The Rockwell superficial hardness for the T scale is denoted by the symbol HR preceded by the hardness

understanding rockwell hardness scale

The King Of Fighters 97. The King Of Fighters 98. The King Of Fighters 99. The King Of Fighters 2000. The King Of Fighters 2001. The King Of Fighters 2002. The King Of Fighters 2003. The King Of Fighters 2004 Edicion Especial (Requiere KOF02) The King Of Fighters 10th Anniversary 2005 Unique (Requiere KOF02)

rockwell hardness test scale b|rockwell b hardness scale chart